Boost CIP efficiency with Conductivity & Turbidity working together

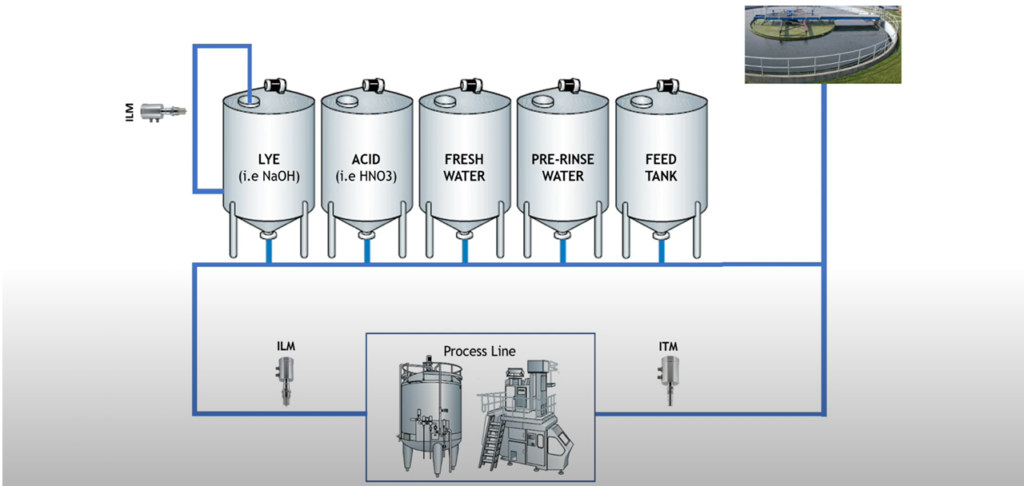

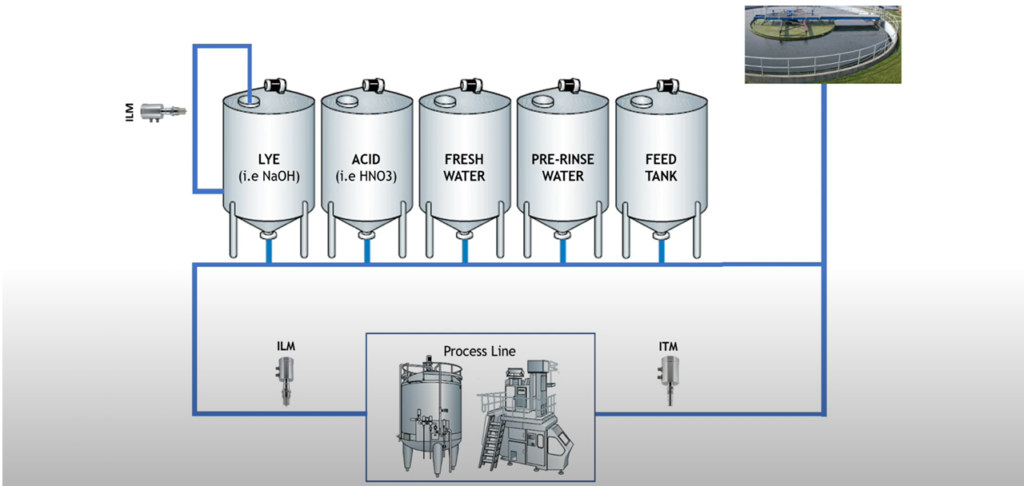

By using the ILM-4 & ITM-51 as a team you can help minimize waste, boost product yield and recover “clean” cleaning agent over traditional methods of monitoring such as sight glass or timing calculations.

The ILM-4 provides the traditional interface monitoring for CIP sequences using conductivity, but the efficiency boost really comes from the ITM-51s turbidity monitoring. The ITM-51 allows post process line to more accurately monitor and retain the following;

- Product & pre-rinse interface

- Clean & Dirty pre-rinse

- Clean & Dirty cleaning agent

- Trade waste with too high TDS

All by installing 1 or 2 sensors into your process line we can save easy dollars for your business.

Keep product off the floor and on shelves

With many customers mindful of choosing products which are actively trying to reduce waste and minimize any harmful impact they have on the environment, along with competitive nature of supermarket shelves. It is now more than ever you need to make sure you are getting as much product in packing as possible and keeping it off the floor.

Making compromises on install to save, might cost you three to four times as much in the long run. Not to mention all the electricity and raw materials that when into process the product just for it to be thrown out before making it to the shelves for sale.

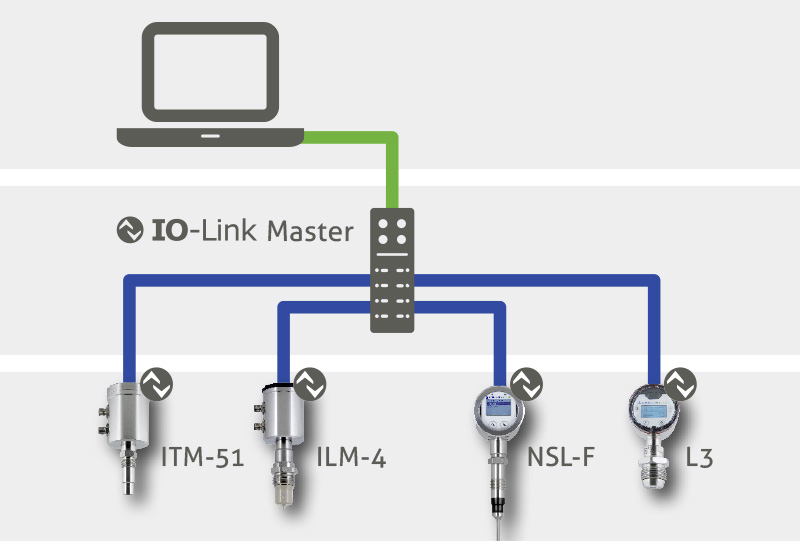

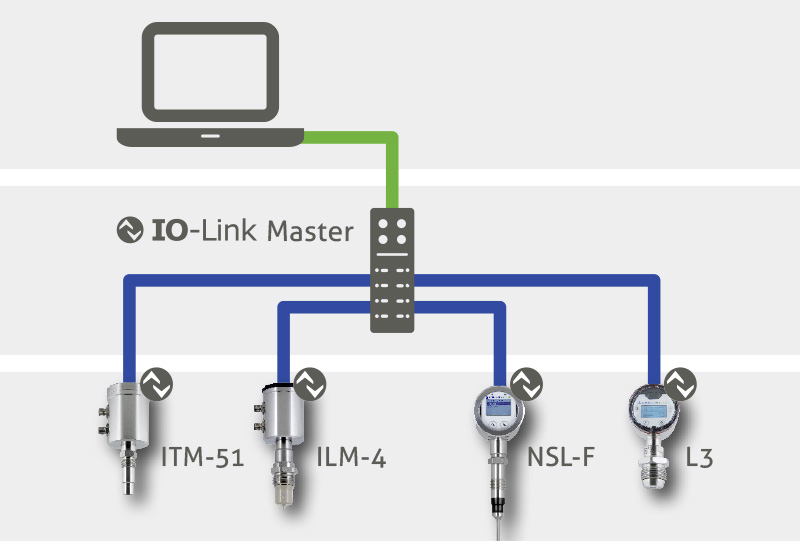

How IO-Link is the way of the future for industrial manufacturing

IO-Link brings a whole new world of data gathering to your site, with a data rich communication interface with a range of equipment. With plug & play easy similar to USB

The 5 Key Advantages being;

- Standardised Wiring & Reduced Wiring (Cost savings)

- Increase data availability (including diagnostic/event data)

- Remote configuration and monitoring

- IO-Link saves device settings to automatically updated a replacement

- Extended data for both process, service and potential early failure detection

Anderson-Negele's ILM-4 Conductivity Sensor now with a 5-Year Manufacturer Warranty

For over 10 years, conductivity measurement with the Anderson-Negele ILM series of sensors has become synonymous with phase separation in CIP skids in the food & beverage industries. The current generation ILM-4 is based on the modular platform with the digital communication technology IO-Link, in addition to dual 4…20mA Cond/Temp outputs.

Anderson-Negele has such confidence in their product that until 30 April 2021 all ILM-4 series conductivity sensors will come with a 5-Year manufacturer warranty.

More News Coming Soon

Please check back later for our latest news stories